| SPECIFICATIONS FOR LSAW STEEL PIPE | |

| 1.Size | 1)OD:406mm-1500mm |

| 2)Wall Thickness: 8mm-50mm | |

| 3)SCH20,SCH40,STD ,XS,SCH80 | |

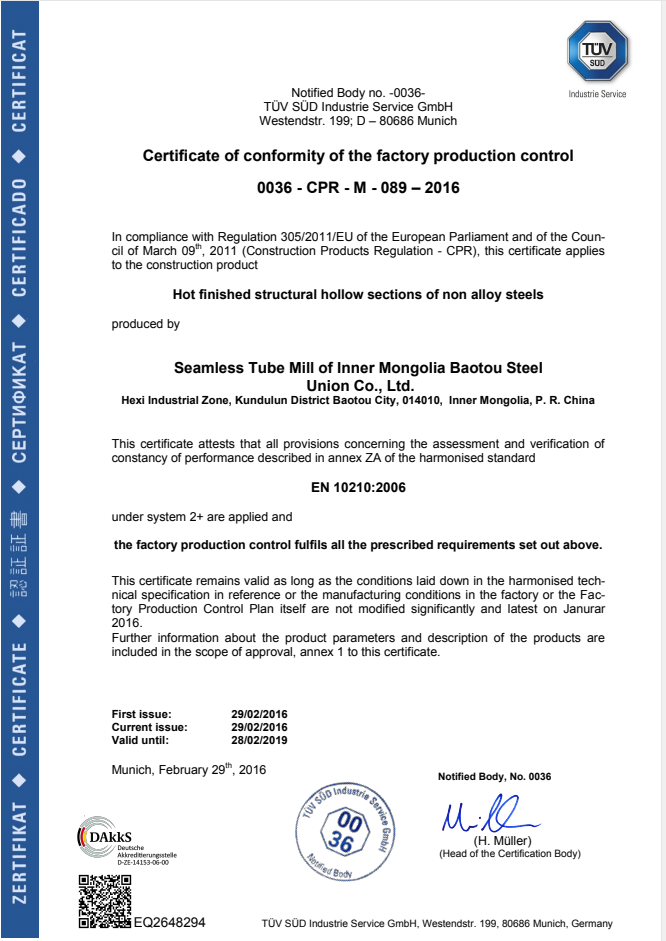

| 2.Standard: | ASTM A53,API 5L,EN10219,EN10210,ASTM A252 ,ASTM A500etc |

| 3.Material | ASTM A53 Gr.B,API 5L Gr.B,X42,X52,X60,X70,X80,S235JR,S355J0H ,etc |

| 4.Usage: | 1)low pressure liquid, water, gas, oil, line pipe |

| 2)structure pipe, pipe piling construction | |

| 3)fence, door pipe | |

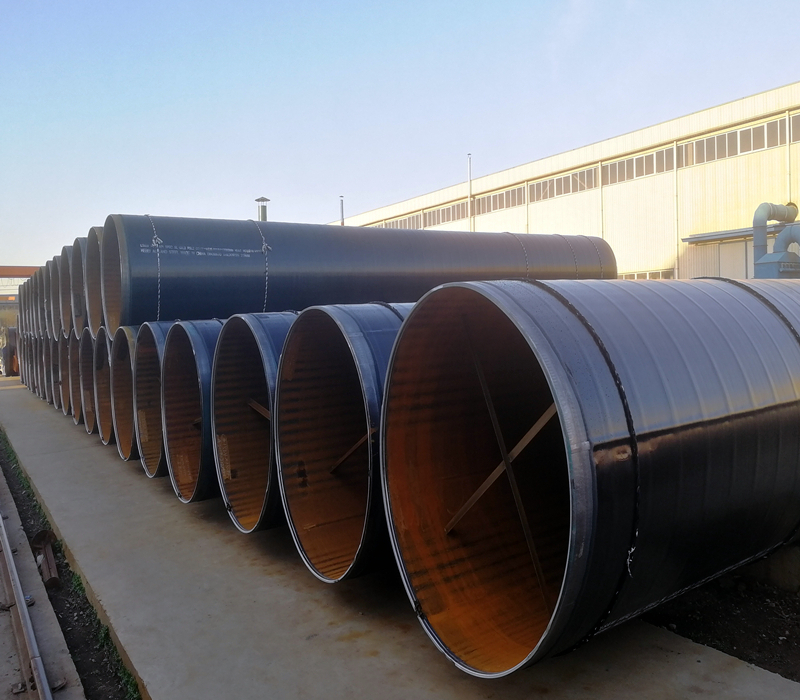

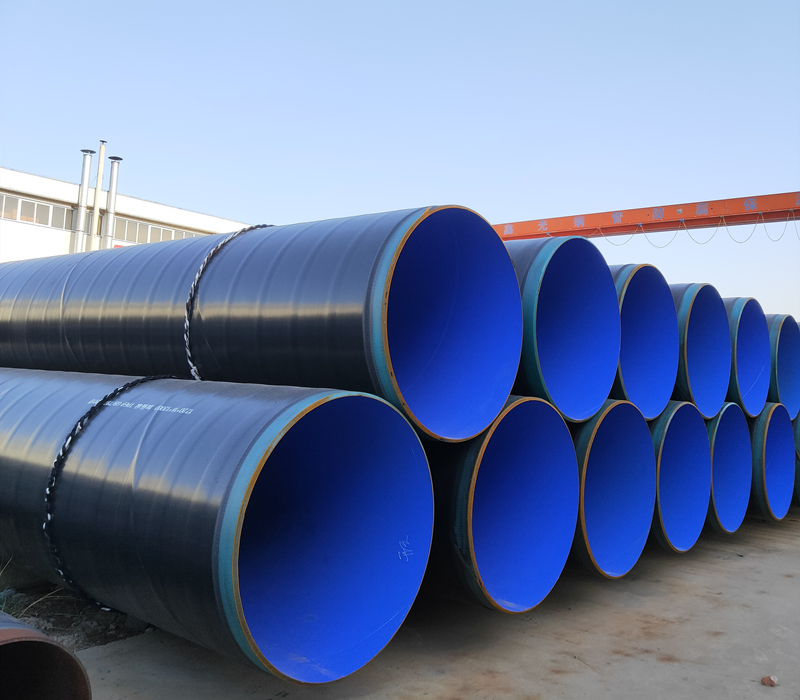

| 5.Coating | 1) Bared 2) Black Painted (varnish coating) 3) Galvanized 4) Oiled 5) PE,3PE, FBE, comosion resistant coating, Anti corrosion coating |

| 6.Technique | longitudinal welded steel pipe |

| 7. Inspection: | With Hyd raulic Testing, Eddy Current, RT, UT or inspection by 3rd party |

| 8.Delivery | Container, Bulk Vessel. |

| 9.About Our Quality: | 1) No damage, no bent 2) no burrs or sharp edges and no scraps 3) Free for oiled&marking 4) All goods can be checked by third party inspection before shipment |

Engineering case of Hong Kong

Engineering case of Qatar

Engineering case of Turkey

LSAW Pipe adopts submerged arc welding technology, using filler welding, particle protection flux buried arc.

LSAW is the English abbreviation of submerged arc welded straight seam steel pipe. The production process of submerged arc welded straight seam steel pipe includes JCOE forming technology, coil forming submerged arc welding technology and UOE forming technology.

The process of manufacturing Longitudinal Submerged-arc Welded(LSAW) Pipe is as follows:

Ultrasonic plate probing → edge milling → pre-bending → forming → Pre-welding → Internal welding→ External welding → Ultrasonic inspection → X-ray inspection → Expanding → hydraulic test →l. Chamfering → Ultrasonic inspection → X-ray inspection → magnetic particle inspection at tube end

|

Tensile Requirements |

|||

|

Grade 1 |

Grade 2 |

Grade 3 |

|

| Tensile strength, min, psi (MPa) |

50 000 (345) |

60 000 (415) |

66 000 (455) |

| Yield point or yield strength, min, psi(MPa) |

30 000 (205) |

35 000 (240) |

45 000 (310) |

| Basic minimum elongation for nominal wall thicknesses %6 in. (7.9 mm) or more: Elongation in 8 in. (203.2 mm), min, % Elongation in 2 in. (50.8 mm), min, % |

18 30 |

14 25 |

... 20 |

| For nominal wall thicknesses less than %6 in. (7.9 mm), the deduction from the basic minimum elongation in 2 in. (50.08 mm) for each Vzi - in. (0.8 mm) decrease in nominal wall thickness below %6 in. (7.9 mm), in percentage points |

1.5A |

1.25A |

1.0A... |

Hydrostatic Testing

NDT(RT) Testing

NDT(UT) Testing

Bending Test— a sufficient length of pipe shall stand being bent cold through 90° around a cylindrical mandrel.

Flattening test-although testing is not required ,pipe shall be capable of meeting the flattening test requirements.

Hydro-static test—except as allowed ,each length of pipe shall be subjected to the hydro-static test without leakage through the pipe wall.

Nondestructive electric test-as an alternative to the hydro-static test ,the full body of each pipe shall be tested with a nondestructive electric test . where nondestructive electric test is performed,the lengths shall be marked with the letters”NDE”

The ultrasonic testing

The eddy current examination

Bare pipe, black coating ( customized);

Both ends with end protectors;

Plain end, bevel end;

Marking.

| Outside Diameter | The outside diameter of pipe piles shall not vary more than ±1% from the specified outside diameter. | ||

| Wall thickness | The wall thickness at any point shall not be more than 12.5% under the specified nominal wall thickness. | ||

| Lengths | Pipe piles shall be furnished in single random lengths, double random lengths, or in uniform lengths as specified in the purchase order, in accordance with the following limits: | Single random lengths | 16 to 25ft (4.88 to 7.62mm), inch |

| Double random lengths | Over 25ft (7.62m) with a minimum average of 35ft (10.67m) | ||

| Uniform lengths | length as specified with a permissible variation of ±1 in. | ||

| Weight | Each length of pipe pile shall be weighed separately and its weight shall not vary more than 15% over or 5% under its theoretical weight, calculated using its length and its weight per unit length. | ||