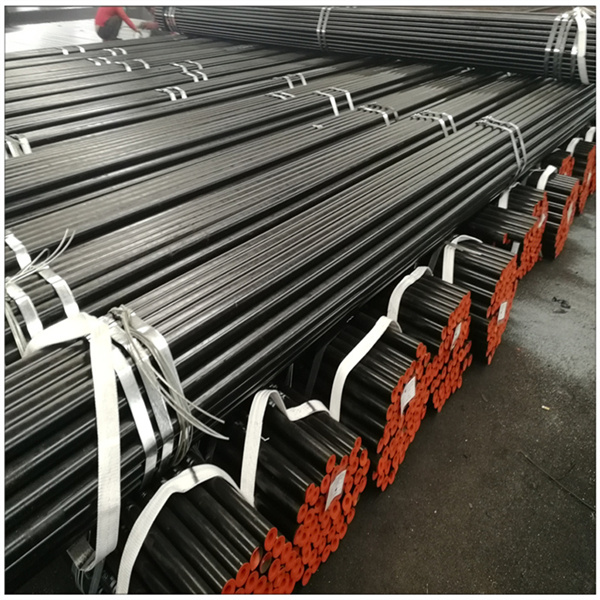

| Product Name | Carbon Steel Seamless / Ms Steel Pipe |

| Standard | ASTM A106,ASTM A53,API 5L Gr.B, DIN17175,DIN1629 |

| Outer Diameter: | 13.7mm-762mm |

| Wall Thickness | 2mm-80mm |

| Dia Tolerance | Control with in the standard, OD:+-1%,WT:+-10% |

| Materials | 10#,20#,45#,16Mn,A106(B,C),A53(A,B),API 5L (GR.B,X42/X52/X56/X65) API 5CT(H40,J55,K55,N80,P110),Q235,Q345,ST35.8,ST37,ST42,ST45,ST52 |

| Inspection | ISO,BV,SGS,MTC |

| Packing | 3LPE/3PP/FBE/BLACK painting/Varnish, and steel strip packed,Standard Export Seaworthy Package,or as required |

| Supply Ability | 1000 metric tons/month |

| MOQ | 5metric ton,sample order accepted |

| Shipment time | Within 7-10 workdays after receiving deposit or L/C |

| Payments | T/T,LC |

| Capacity | 250,000 tons/year |

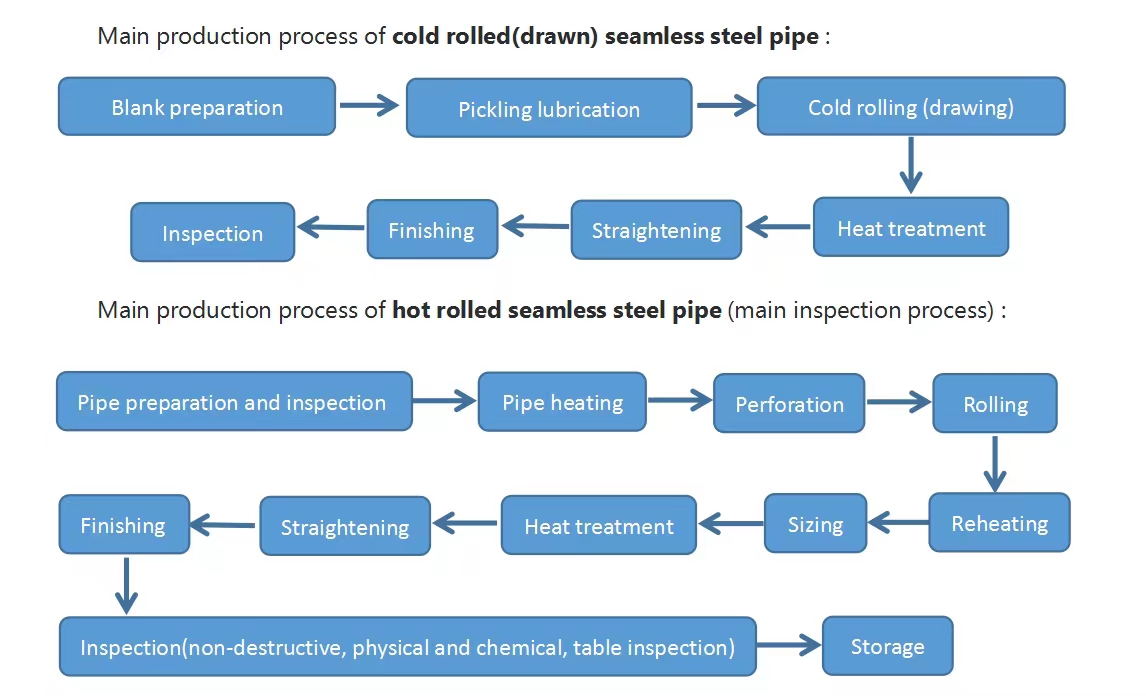

API 5L Gr. X52NS PSL 2 Seamless Steel Pipe ACC.To IPS-M-PI-190(3) & NACE MR-01-75 is always used in sour environment especially in oil and gas fields with H2S and CO2 rich gas.

API 5L X52NS PSL 2 Seamless Steel Pipe ACC.To IPS-M-PI-190(3) & NACE MR-01-75 for sour service must do heat treatment after production. And should do HIC and SSC tests.

Grade and Chemical Composition (%) For API 5L PSL2

|

Standard |

|

Chemical composition(%) |

|

|

||||

|

C |

Mn |

P |

S |

Si |

V |

|||

| API 5L |

X52 NS |

≤0.16 |

≤1.65 |

≤0.02 |

≤0.003 |

≤0.45 |

V ≤0.10 |

|

CEⅡW=C+Mn /6+(Cr+Mo+V) /5+(Cu+Ni) /15 ≤0.39

Nb+V+Ti≤0.15%

Nb+V≤0.06%

When do product chemical analysis, two analyses per heat of steel taken from separate product items

Mechanical Properties of API 5L X52NS PSL 2 Seamless Steel Pipe ACC.To IPS-M-PI-190(3) & NACE MR-01-75 for sour service:

|

Yield Strength(MPa) |

Tensile Strength(MPa) |

Elongation A% |

|

MPa |

MPa |

Elongation (Min ) |

|

36O-530MPa |

460-760MPa |

20 |

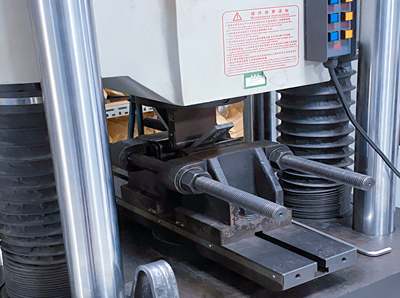

Bend Test

Mechanical Properties Test

Hardness Test

Finished pipe OD WT length, surface quality, Straightness, polishing the defected pipe Visual and Dimensional Inspection.

1. OD tolerance: (-0.75%D,+0.75%D).

Pipe ends OD tolerance: ±0.005D.

2.WT tolerance: (+15%t, -12.5%t).

3. Ovality of pipe body: ±0.020D, Ovality of ends: ±0.015D.

The WT at any point of the pipe shall be more than 87.5% of nominal wall thickness.

WT on pipes ends is measured with micrometer.

Wall thickness measuring on pipe body is performed by manual UT for WT covering 3 rings or section all along the pipe body with 6 readings at each section.

4. Pipe body bend degree:0.20% of the pipe length Measured with a taught line.

5. Pipe end bend degree : Should not be more than 3.0mm in 1.2m. Measured with a straight bar.

Out Diameter Inspection

Wall Thickness Inspection

End Inspection

Straightness Inspection

UT Inspection

Appearance Inspection

Bare pipe or Black / Varnish coating ( according to customer;s requirements);

6" and below in bundles with two cotton slings;

Both ends with end protectors;

Plain end, bevel end(2" and above with bevel ends, degree: 30~35°), threaded and coupling;

Marking.

Seamless Pipe Ship to Qatar

Seamless Pipe ship to Pakistan

Seamless Pipe Ship to South Africa

Seamless Pipe ship to Ecuador